Unlike indoor environments, outdoor display products must face multiple harsh tests including direct sunlight, rain, seasonal temperature differences, and dust intrusion.

Therefore, determining its core quality, in addition to the chip itself, lies more in the packaging technology—it protects the chip and determines the form of light, efficiency, and the final reliability of the product.

Currently on the market, DIP and SMD are the mainstream LED packaging technology routes. They each have their own characteristics and are suitable for different outdoor scenarios and needs. This article will conduct an in-depth comparative analysis of the principles, performance pros and cons, and outdoor applicability of these technologies, providing a clear decision-making basis for your choice.

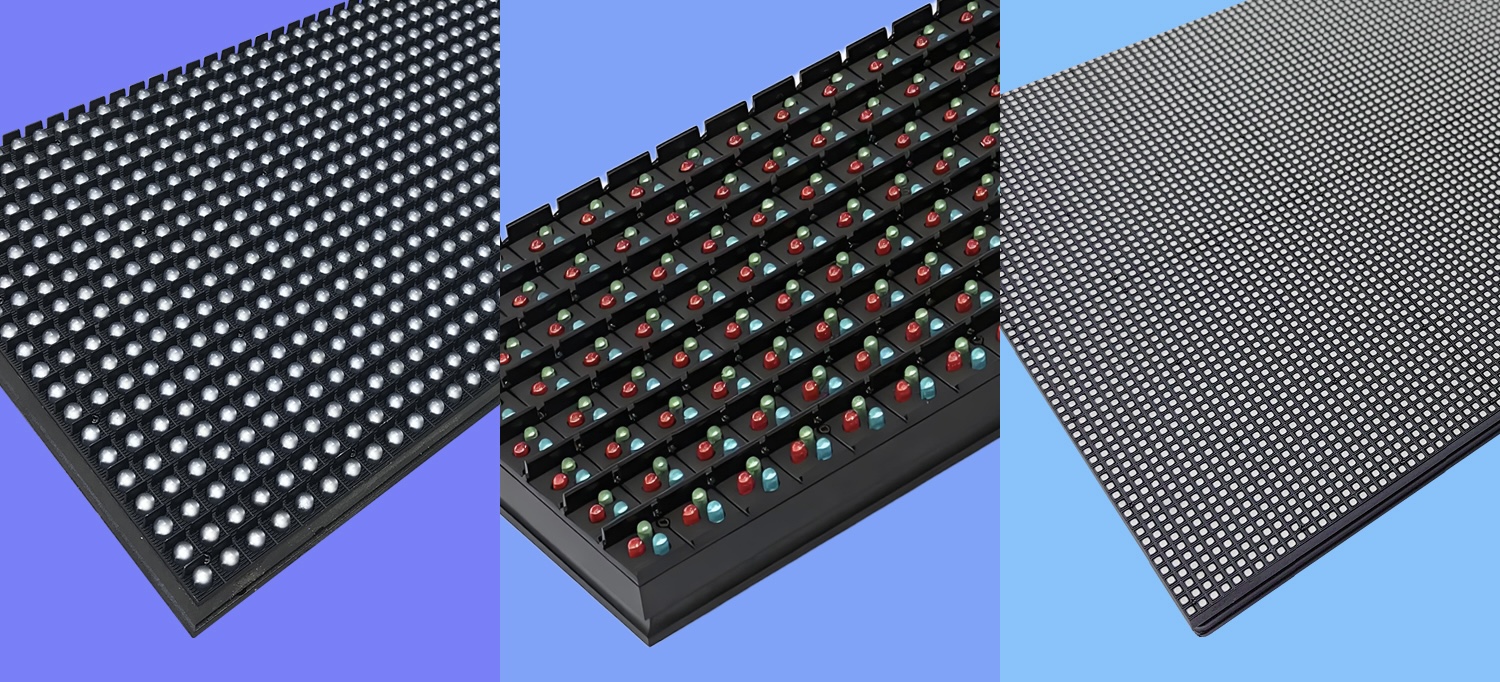

To understand their outdoor performance, we first need to understand their fundamental structural differences.

DIP is the traditional packaging form with the longest development history, commonly known as "plug-in lamp." Its process involves directly inserting the long pins of individual LED beads (monochrome in early stages, later integrating RGB three-color chips) into corresponding holes on the PCB board, and then fixing them through wave soldering. Due to its relatively simple and mature structure, it was once the absolute mainstay of outdoor displays.

SMD represents a more mainstream modern packaging process. It first packages tiny LED chips into very small, pinless surface-mount components, then quickly and accurately mounts them onto the surface of the PCB board using high-precision automated placement machines. The widely used "tri-in-one" SMD technology encapsulates red, green, and blue three chips in the same gel body, thus becoming the basic unit for displaying a pixel.

MiniLED is not an entirely new packaging method, but can be seen as a combination and evolution of the extreme miniaturization of SMD technology and integrated technology routes such as COB (Chip On Board). By using smaller LED chips with dimensions of 100-300 microns and adopting more precise matrix-integrated packaging (such as COB), it integrates orders of magnitude more LED beads per unit area, thereby achieving finer partition control, higher brightness, and contrast.

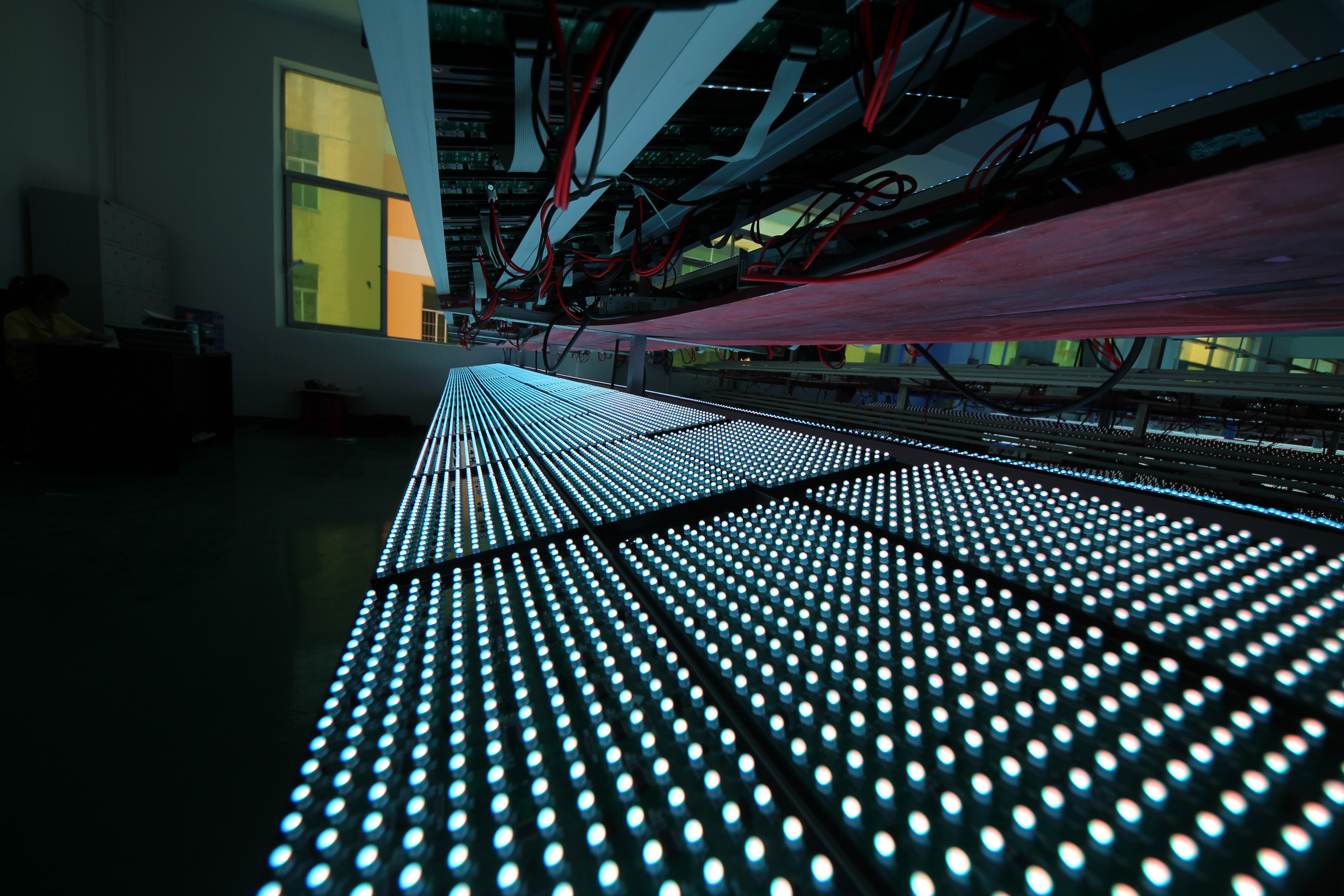

Kingaurora's outdoor LED displays are known for their excellent wind resistance, high transparency, and outstanding weather resistance, capable of stable operation under various extreme weather conditions. Whether it's high temperatures, strong winds, or complex lighting environments, Kingaurora displays ensure content clarity and visibility.

With its technical strength and industry reputation, Kingaurora continues to promote innovation and progress in display technology, helping more enterprises and institutions engage in closer and more effective interaction and communication with the public through this innovative technology.

To visually demonstrate the performance of the three in outdoor environments, we conduct a quantitative comparison and analysis from the following five key dimensions:

| Comparison Dimension | DIP (Plug-in) | SMD (Surface Mount) | MiniLED (including COB) |

|---|---|---|---|

| Protection & Durability | Extremely High

Bead structure is sturdy, pin soldering is firm, and usually has mask protection, with excellent waterproof, moisture-proof, and impact resistance capabilities. |

Beads are exposed on the PCB surface. Although encapsulated in gel, resistance to complex outdoor environments (waterproof, moisture-proof, anti-oxidation) is its traditional weakness. |

Taking COB form as an example, chips are integrally encapsulated and solidified on the PCB board with epoxy resin glue, with a smooth and hard surface, no exposed solder joints, achieving true "six-proof" (waterproof, moisture-proof, dust-proof, impact-proof, oxidation-proof, static-proof). |

| Brightness & Contrast |

High brightness, meeting basic outdoor requirements. But fixed viewing angle (usually 100-110 degrees), average light efficiency, limited contrast improvement. |

Good

Good brightness performance, can be improved through chip technology. Wider viewing angle (120-140 degrees). Contrast limited by packaging form. |

Can achieve ultra-high brightness (>10,000 nits), and through fine partition light control, can present ultimate dark detail and high contrast. New technology can achieve 100% BT.2020 wide color gamut. |

| Pixel Density & Resolution |

Limited by bead physical size, pixel pitch difficult to reduce, currently mainstream at P6 and above, suitable for long-distance viewing. |

High

Can achieve pixel pitch from P10 to P2 or even smaller, meeting medium-close distance high-definition display requirements, currently mainstream for HD outdoor screens. |

Benefiting from chip miniaturization, pixel pitch can easily break through P2, entering the micro-pitch field below P1.0, presenting ultra-high-definition images at close distances. |

| Heat Dissipation & Stability |

Long heat dissipation path (through pins), average heat dissipation efficiency, significant light attenuation with prolonged use. |

Heat mainly dissipated through gel and pads, limited heat dissipation area, chip heat concentrated. |

Chips directly contact PCB board over large area, rapid heat conduction through copper foil, high heat dissipation efficiency, effectively reducing light attenuation, extending lifespan. High stability, extremely low bad pixel rate. |

| Energy Consumption & Maintenance |

Relatively high energy consumption. In maintenance, single bead replacement seems direct, but overall process is complex, reliability varies between batches. |

Good

Moderate energy consumption. Standardized modules support front and rear maintenance, individual module replacement is convenient. |

Excellent energy consumption performance. Using common cathode drive and other energy-saving designs, power consumption can be reduced by 40% compared to traditional products. COB packaging maintenance is simple, supports point-by-point repair, but requires professional equipment. |

Different performance characteristics naturally point to different application scenarios and market positioning.

Core Positioning: Cost-priority large long-distance information transmission.

Best Scenarios: Suitable for occasions where image fineness requirements are not high, but strong durability and cost control are needed.

Typical Applications: Large billboards beside highways, long-distance identification on building tops, long-distance scoreboards in sports venues, etc. Currently still holds strong share in P20-P8 market.

Cost Analysis: Lowest initial procurement cost, low production process threshold, fierce market competition. But comprehensive consideration of its higher energy consumption and possible maintenance costs is needed.

Core Positioning: Performance and cost balanced outdoor HD display main force.

Best Scenarios: Suitable for most commercial scenarios requiring image clarity and relatively close viewing distance.

Typical Applications: Shopping mall exterior wall advertising screens, store signs, municipal information release screens, rental performance screens, etc.

Cost Analysis: Thanks to automated production and scale effects, its cost-performance ratio is very high, currently the absolute mainstream choice in the outdoor HD display market. Deficiencies in protection can be compensated by adding protective masks and other external measures.

Core Positioning: High-end solution pursuing ultimate display effects, high reliability, and creative forms.

Best Scenarios: Suitable for landmark projects with sufficient budget and strict requirements for picture quality and reliability.

Typical Applications: Urban landmark building media facades, high-end commercial complex creative screens, outdoor ultra-HD studio background screens, and harsh environments requiring extreme weather resistance.

Cost Analysis: Highest initial procurement cost, involving high technical thresholds in chips, packaging, drives, etc. But its excellent stability, energy saving, and low maintenance requirements may make long-term comprehensive usage costs more advantageous.

The selection of outdoor LED displays is essentially precise matching between project requirements, environmental conditions, and budget constraints.

Choosing DIP means choosing a pragmatic solution for long-distance scenarios with extreme emphasis on protection and minimum initial investment. The Kingaurora DIP570 series, through technological innovation, significantly improves energy efficiency and reliability while maintaining traditional DIP advantages, injecting new vitality into this classic technology.

Choosing SMD means choosing the market mainstream path that achieves the best balance between HD display, cost control, and wide application.

Choosing MiniLED (especially COB technology) means embracing the future—investing more to obtain top-level picture quality, unparalleled reliability, rich creative possibilities, and long-term operational benefits.

From a technological trend perspective, DIP's market share is gradually shrinking due to its technical bottlenecks, but manufacturers like Kingaurora continue to provide optimized solutions for specific application scenarios through continuous innovation; SMD maintains a solid position in the mid-to-high-end outdoor market due to its strong applicability; while MiniLED and the advanced integrated packaging technologies it represents (such as COB, MIP), with their comprehensive advantages in brightness, contrast, reliability, and energy saving, are penetrating from the high-end market downward, becoming the core driving force for outdoor displays to develop towards higher picture quality, more intelligence, and greater energy efficiency.

In the future, as MiniLED costs further decrease and more innovative packaging technologies emerge, the picture of outdoor display will surely become clearer, more vivid, and more绚丽. As an industry innovator, Kingaurora will continue to provide the most suitable display solutions for customers with different needs through technological progress.

3th Building,Gaosite Zone Pingshan

New District, Shenzhen

sevice88@kingaurora.com

3th Building,Gaosite Zone Pingshan

New District, Shenzhen